FREE SHIPPING ON

ORDERS $500+

One of the largest questions I ask myself with the slow but steady acknowledgement of the harms of plastics is how to make replacement options. Plant-based polymers are gaining in popularity, however, there is a finite amount of arable land on this planet. Crops need resources to grow and using the best destination for that acreage is a major question that will have to be addressed in the upcoming years. Does it make sense to grow corn for people or fuel? How can we make utensils from biodegradable sources without making the world’s citizens hungry?

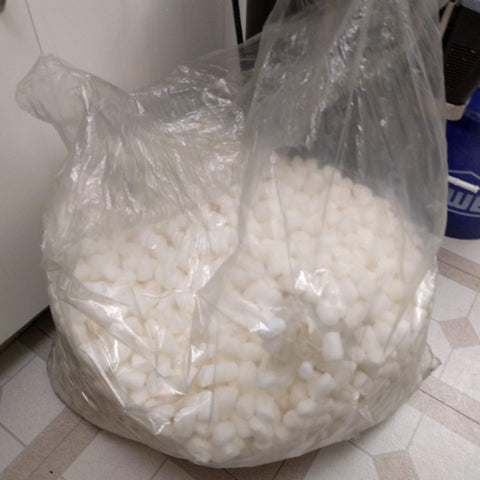

One answer I have determined is that if we can use the biodegradable tools after in other processes instead of directly to the landfill, we could get two uses of the same material. The easiest that I thought of was to use starch-based packing peanuts in a beer. These packing peanuts are basically cheezies without the cheese, a corn or potato starch is extruded and made into a lightweight pellet. (Whitford, 1996)

If the packing peanut is made from starch, which is basically white flour, it can be used as an adjunct. That means you can make beer from packing peanuts. The important aspect is if the beer tastes good afterwards. Additionally, just because something is food grade, does not mean that it is fit for consumption. Knives are food grade, but we don’t eat those.

Figure 1 - Required Packing Peanuts

Figure 2 - Adding the Packing Peanuts to the Strike Water

SG 1.055, FG 1.008

Attenuation = 85.4%

Alcohol = 6.3 ABV

Appearance: Golden with a touch of orange.

Aroma: Low-Moderate Bread and Toast Malt. Moderate-High Payaya, Grapefruit, and Anise Hops. Moderate Phenol.

Flavour: Moderate Light Toast Maltiness. Moderate-High Payaya & Grapefruit. Moderate Phenol.

Mouthfeel: Dry, Low-Moderate Body. Moderate Carbonation with a lasting head.

Finish: Lingering phenol with some hoppy notes. Slight astringency.

General Impression: Slightly dry for style, malt characters were present, and the new age hop variety was pleasant, however, the phenol was a considerable note and detracted from the beer.

The brewing day was complicated by the addition of the packing peanuts. Due to their low density, about 3-4 volumes of packing peanuts are required per volume of beer. While promised to be fully biodegradable and dissipate with water, the dissolution took much longer and much more effort than originally intended. This would not lend well to industrial brewing practises as the volume required for the extract is not practical.

Figure 3 - Trying to Dissolve the Packing Peanuts

The beer fermented with an overall attenuation of approximately 85.4%. This makes sense as the packing peanuts should have polysaccharides that are completely broken down by the amylases found in the malt. This would increase the attenuation of the yeast to above the 70-80% of the manufacturer. A higher mashing temperature should have been used to counter the high hop accentuations reported by the manufacturer (Escarpment Labs, 2020). The alcohol was higher than expected, the lower residual sugar would aid in beer consumption but would allow for flaws to be more present. The colour of this beer was nice and pleasant. The beer flavour was in line for style, but the distracting factor from the phenols. Since the water was treated for chlorine from the municipal source, it is presumed that the phenolic off note has come from an unknown additive or a contaminant from the packing peanuts.

Figure 4 - The final product

Combined with the material handling issues with the potential for phenolic off flavours, packing peanuts are not an ideal adjunct. However, if they were compacted and used for fuel ethanol as a sugar source, they may have a much better practical application.

Escarpment Labs, 2020. Strain Collection. [Online]

Available at: https://www.escarpmentlabs.com/

[Accessed 22 06 2020].

Whitford, D., 1996. The Snack Food That's Packing America. [Online]

Available at: https://www.inc.com/magazine/19961001/1828.html

[Accessed 13 06 2020].

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}